Specialty Films & Printing Media

Advanced film solutions for printing, protection, and industrial applications

TRU DIGI – NON-TEARABLE PHOTO PAPER (LMO)

Product Description

TRU DIGI is a white, opaque matte PET film with coating on both sides, specially designed for digital printing applications. The film offers excellent print quality, durability, and tear resistance.

It is ideal for wedding albums, visiting cards, signage, and posters.

Technical Specifications

Material: PET Film (Polyester Film)

Thickness: 100 to 200 microns

Film Color: White Matte

Surface Finish: Matte, double-side coated

Printing Compatibility: Digital Printing

Pack Size: 200 sheets per pack

Available Sizes

-

330 × 482 mm

-

305 × 457 mm

-

318 × 330 mm

Other sizes can be manufactured on a minimum order quantity of 5,000 sheets.

Shelf Life

2 years from the date of manufacturing when stored at 25–30°C and 55% RH.

SURFACE PROTECTION FILM (MASKING FILM)

Product Description

Surface Protection Film is a single-side coated LDPE-based film designed to protect surfaces from scratches, dust, and transportation damage. It is widely used across industries such as metal and stainless steel sheets, plastic sheets, decorative laminates, and aluminium composite panels.

This film offers an easy, economical, and environmentally friendly solution for surface protection. The self-adhesive or heat-activated film is laminated onto the surface during processing and removed after the final stage, ensuring the surface remains intact and damage-free.

Technical Specifications

Material: PE Film (Polyethylene)

Thickness: 30 microns to 120 microns

Width: Up to 1550 mm

Paper Core ID: 76 mm

Film Color: Transparent or Opaque (other colours available on request)

Printing: Available

Applications

-

Metal and stainless steel sheets

-

Plastic sheets

-

Decorative laminates

-

Aluminium composite panels

SOLAR BACK SHEET (TRU-SOLAR)

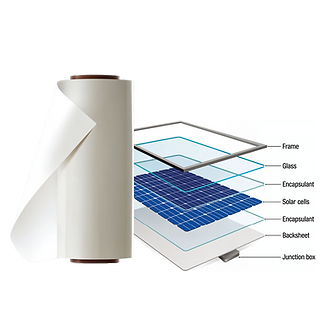

Product Description

TRU–Solar Back Sheet is a high-performance PV back sheet designed to protect photovoltaic modules from UV radiation, moisture, and harsh weather conditions, while providing reliable electrical insulation.

As the outermost layer of a solar PV module, the back sheet safeguards the photovoltaic cells and internal electrical components from environmental and mechanical stresses. Its robust laminate construction ensures long-term durability and stable performance in outdoor applications.

Technical Specifications

Material: PET + EVA Primer / PET + PET + EVA Primer

Thickness: 200 microns – 300 microns

Width: 1000 mm & 960 mm

Custom Width: Up to 1550 mm (as per order)

Paper Core ID: 76 mm or 150 mm

Key Attributes

-

UL-certified 3-layer back sheet

-

Excellent interlayer adhesion retention after environmental aging

-

Outstanding colour and mechanical property retention under UV exposure

-

High mechanical strength and durability

INSULATION INDUSTRY

PRODUCTS

A range of laminates combining plastic films and foil, providing aesthetic finishes and acting as barriers to protect insulating materials from external environments. Key offerings include:

-

PVC Cladding (230 micron and 350 micron)

-

ALU–PET Laminate for XLPE and NBR Foam

-

MET PET Laminate

-

PE Foil Laminate

-

Embossed Foil

-

Glass Cloth to PE Laminate

-

Self-Adhesive Glass Cloth and Aluminium Foil

ALUMINIUM INDUCTION SEALING WAD

Product Description

Aluminium Induction Sealing Wads are used to seal containers securely and protect their contents from air, moisture, and external contamination. These wads provide an airtight seal, ensuring product freshness while preventing leakage, tampering, or adulteration.

Once sealed, the wad cannot be removed and reapplied without visible damage, making it an effective tamper-evident solution for a wide range of industries.

Sealing Process

After the container is filled and capped, an induction current is passed through the aluminium foil layer within the sealing wad. This generates heat, activating the polymer layer laminated to the foil, which melts and bonds securely to the mouth of plastic or glass containers.

The sealing process is completed within seconds and does not affect the container or its contents, as no direct heat is applied.

Key Benefits

-

Leak prevention and protection

-

Maintains product freshness

-

Tamper-evident sealing

-

Airtight and secure closure

Application Areas

-

Pharmaceutical industries

-

Food and beverage industries

-

Chemical industries

-

Automobile lubricant industries

-

Beauty and personal care industries

TRU LAM – NON PVC OVER LAMINATION FILM

Product Description

TRU LAM is a non-PVC over lamination film designed to enhance and protect printed media. The film is supplied with silicone release paper and is backed by a high-performance adhesive, ensuring smooth application and long-lasting protection.

This lamination film improves the durability, appearance, and surface protection of printed graphics while maintaining an eco-friendly and recyclable profile.

Available Variants

-

Gloss Lamination Film

-

Matt Lamination Film

-

Texture Lamination Film

Technical Specifications

Thickness: 70 – 100 microns

Adhesive Type: High-performance adhesive

Available Widths: 3 ft, 4 ft & 5 ft

Material Type: Non-PVC

Environmental Profile: Eco-friendly and recyclable

TRU FAB – COATED FABRIC FOR PRINTING

Product Description

TRU FAB is a coated textile printing media made from polyester blended fabric, offering an effective alternative to conventional flex and backlit materials. It delivers exceptional print quality and is suitable for both indoor and outdoor applications.

The material provides excellent flexibility and uniform light dispersion, making it ideal for display, signage, and visual communication applications.

Technical Specifications

Material: Polyester blended fabric

Thickness: 100 microns

Available Widths: 3 ft, 4 ft & 5 ft

Flexibility: High

Light Dispersion: Uniform

Print Quality: Excellent

TRU WALL MEDIA

Product Description

TRU Wall Media is a highly conformable wall application media comprising a release paper and a thin flexible film. The film is designed to adapt easily to various surface textures and contours.

For application, a water-based adhesive is applied to the wall surface, creating a permanent and secure bond between the film and the wall. TRU Wall Media can be used on smooth, rough, flat, or curved surfaces, making it suitable for a wide range of wall graphics and decorative applications.

Key Features

-

Completely eco-friendly

-

Easy application on rough and curved surfaces

-

High durability for outdoor environments

-

Good print quality

TRU ECONYL – NON PVC PRINTING MEDIA

Product Description

TRU ECONYL is a non-PVC printing media specially coated to receive inks and deliver high-resolution image reproduction. The media is backed with a high-performance adhesive and supplied with a paper release liner, ensuring smooth application and strong bonding.

It is compatible with all major printing technologies and offers exceptional print quality with reduced ink consumption, making it an efficient and eco-friendly choice for printing applications.

Technical Specifications

Thickness: 70 – 100 microns

Adhesive Backing: High-performance adhesive

Available Widths: 3 ft, 4 ft & 5 ft

Material Type: Non-PVC

Environmental Profile: Eco-friendly and recyclable